Tirupur

Angeripalayam road

Welcome to Amman Garments

The “Knitting Department” consists of 24 computerised imported knitting machines which can totally knit about 6000 KGs / Day of various qualities of Fabrics such as Jaquard, Vertical Engineered Stripe, Horizontal Engineered Stripes, Pique, Interlock, Rib, 3 Thread Fleece, Terry, Jersey etc. This department also consists of 10 computerised Flat knit machines imported from Japan & Taiwan, Which can produce high quality jacquard, plain collars & cuffs.

The “Processing Department” consists of Soft Flow M/C’s, Specialty Finishing Facilities. This unit is capable of processing 4600 Kgs / Day.

This department is equipped with 2 Calendering M/c’s - 1 from M/s. Fabcon (USA) and another of domestic make. Fabric’s Compacted in these machines have a superior finish with its shrinkage percentage maintained due to the advanced technology of these machines. These machines combined can handle approximately 10,000 Kgs of fabric per day.

The washing Department consists of industrial washing M/C’s doing different type of washing like acid wash, enzyme wash, softner wash etc…. Additional to this we are having 7 tumble dryers. This unit is capable of processing 2500Kgs / Day. The unit also consists of Pigment dyeing M/c which is the one of its kind machine in Tirupur. This can handle 1500 Kgs of garments per day.

The “Printing Department” Consists Of 2 MHM Computerized T-Shirt Printing Machine FROM Austria Which Can Print Up To 8 Colors. The Facility Also Has State Of The Art Curing And Fixing Machine. We Can Print Pigment, Non Pvc, Discharge, Puf, High Density, Photo Print, Glitter Etc In These Machines.

We Have 6 Transfer Fusing Press For Sublimation Printing 7 Transfer Prints. This Unit Can Altogether Handle About 12000 Pieces Of Printing Per Day.

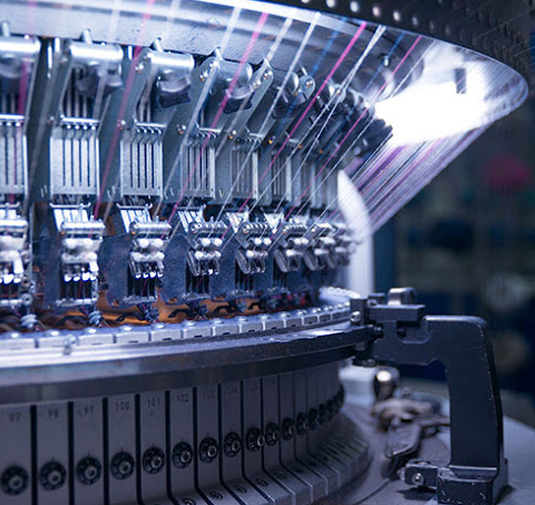

Embroidery department consists of 24 M/C’s with a total of 420 heads latest computerized machines from ‘BARUDAN’ & TAJIMA - JAPAN MAKE. These machines can handle Appliqué, Boring, CHENILLE, SEQUENCE, TAPE EMBROIDERY TECHNIQUES OF EMBROIDERIES Technology. The designing & punching of the embroideries are done in our own punching center.

A brand new carton-manufacturing unit has been set-up. This can manufacture around 1000 cartons per day with necessary specifications.

To sum up, we are proud to inform you that we are one of the very few exporters in Tirupur who have all the necessary infrastructure required for this industry.

Sampling needs are met by specialized section in each division to satisfy the requirements well in time. As all the processing is done in our premises where the style / designs are protected. Sample requests can be met within 15 - 20 days upon receipt of the development sheet.

The “Manufacturing Department” consists of 5 finishing units having a total of 450 m/c including Over lock, Flat lock, Single needle lock stitch m/c, Elastic attachment machine, Scalloping and Picketing machines etc. The total production capacity is 3,00,000 PCs / Month of basic crew neck T-shirts.